How do I make Sticker Sheets?

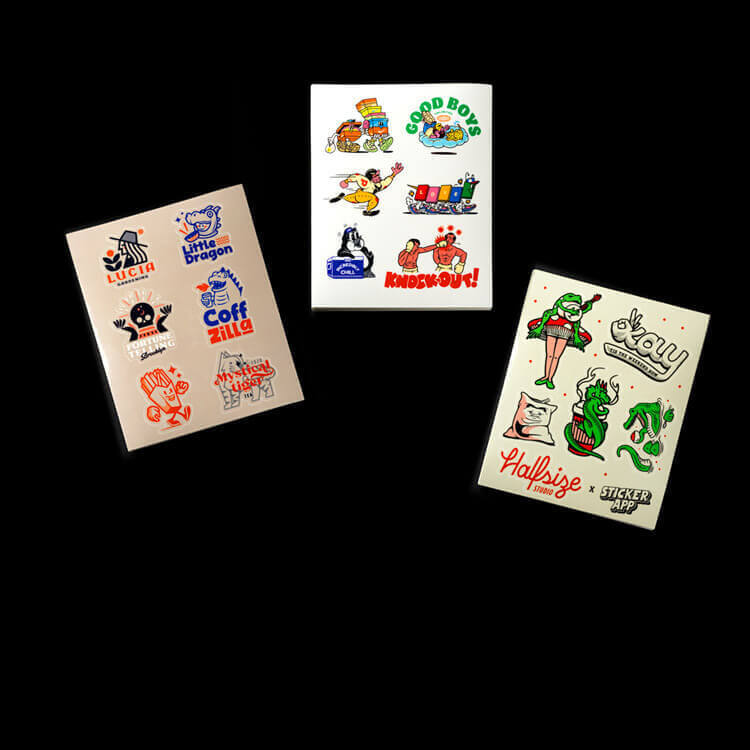

Making your first sticker sheet is easier than you think — even if you’ve never created stickers before! Follow this simple guide, and you’ll have a beautiful, personalized sticker sheet ready to order in just a few minutes.

Creating Effective Sticker Sheets

1. What Is a Sticker Sheet?

A sticker sheet is a single sheet with several stickers on it — like a mini collection. Instead of printing each sticker separately, you put all your designs on one sheet.

Perfect for:

-

small collections

-

themed artwork

-

planner stickers

-

logo packs

-

giveaways

-

kids designs

-

merch for creators

2. Start by Choosing Your Sheet Size

Think about how many stickers you want on one sheet. Most people choose something around 4x6” or 5x7”, but you can go bigger if you want more designs.

You can use any size up to 10.8” x 10.8”.

3. Add Your Sticker Designs

Place your drawings, logos, or artwork onto the sheet. Don’t overthink it — just start dropping them in.

Tips for beginners:

-

Mix big and small stickers to fill the space nicely

-

Keep similar themes or styles together

-

Make sure each design feels “separate” at first

4. Space Your Stickers so They Peel Easily

This is the only technical part — and it’s simple.

Leave a tiny bit of space between stickers: 0.075”/ 2 mm

Why?

So the cut machine knows where to cut and your stickers peel cleanly.

5. Add Cutlines (We Can Help!)

Cutlines tell our machine where your stickers should be cut.

If you’re not used to adding them:

-

Upload your file and use the “cutline” feature

-

Or add a comment to our support → we fix it quickly

This step scares beginners — but we handle it all the time.

6. Choose a Material (Simple Version)

For beginners:

-

Most popular: White vinyl

-

Want clear stickers? Transparent

-

Want shiny? Holographic

-

Want a natural look? Kraft Paper

-

Want glow? Glow in the Dark

You can’t choose wrong — they all look great.

7. Review, Save & Order

Once you’re happy with your layout:

-

check spacing

-

check that nothing touches the edges

-

make sure text is readable

-

make sure each sticker has its own outline

Then just upload it to and place your order!

You’ll receive your finished sticker sheets ready to peel and use.

)